Co-op at Instron: Transverse Extensometer

As part of Northeastern’s Co-op program, I worked at Instron for 6 months from July-December of 2018. One of the projects I worked on an iterative design of their transverse extensometer.

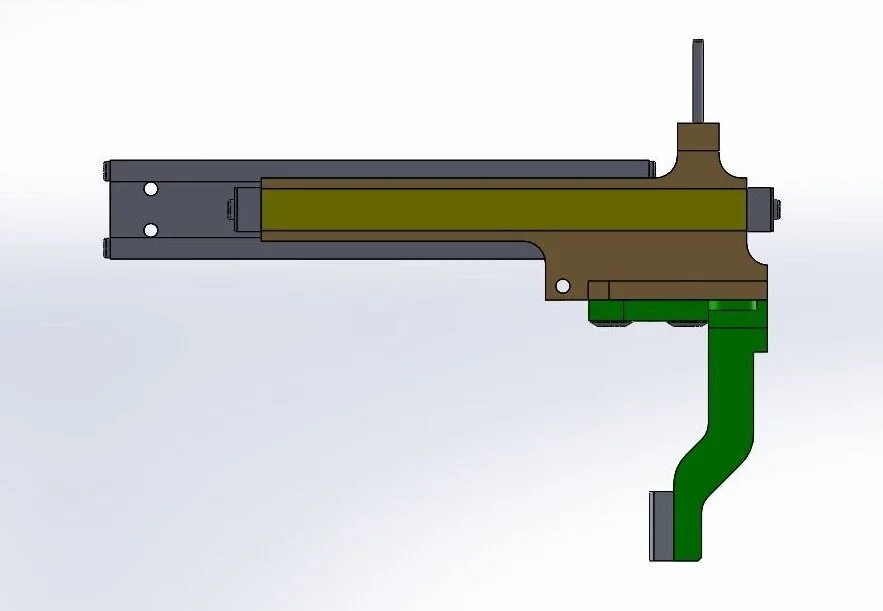

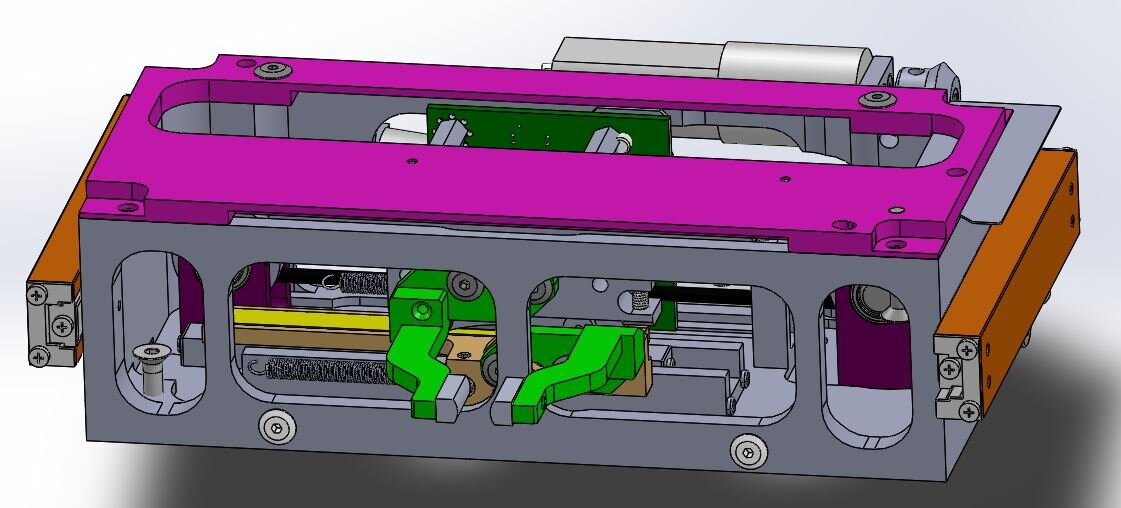

The device worked by “clamping” on to a test specimen with an arm on each side. The arms could move independently from one another and where attached to rollers, so as the specimen’s diameter decreased, the arms would move with the specimen. The arm displacement was then measured by an encoder that read tick marks on a gold plated scale shown on the image to the left below.

The iteration of the design that I was given had 2 main issues.

The device was too expensive.

This was due to the part count being high and the part not easy to machine.

The device was prone to detrimental errors.

If the encoder was not parallel to the scale, it wouldn’t be able to read the displacement and the system would produce an error.

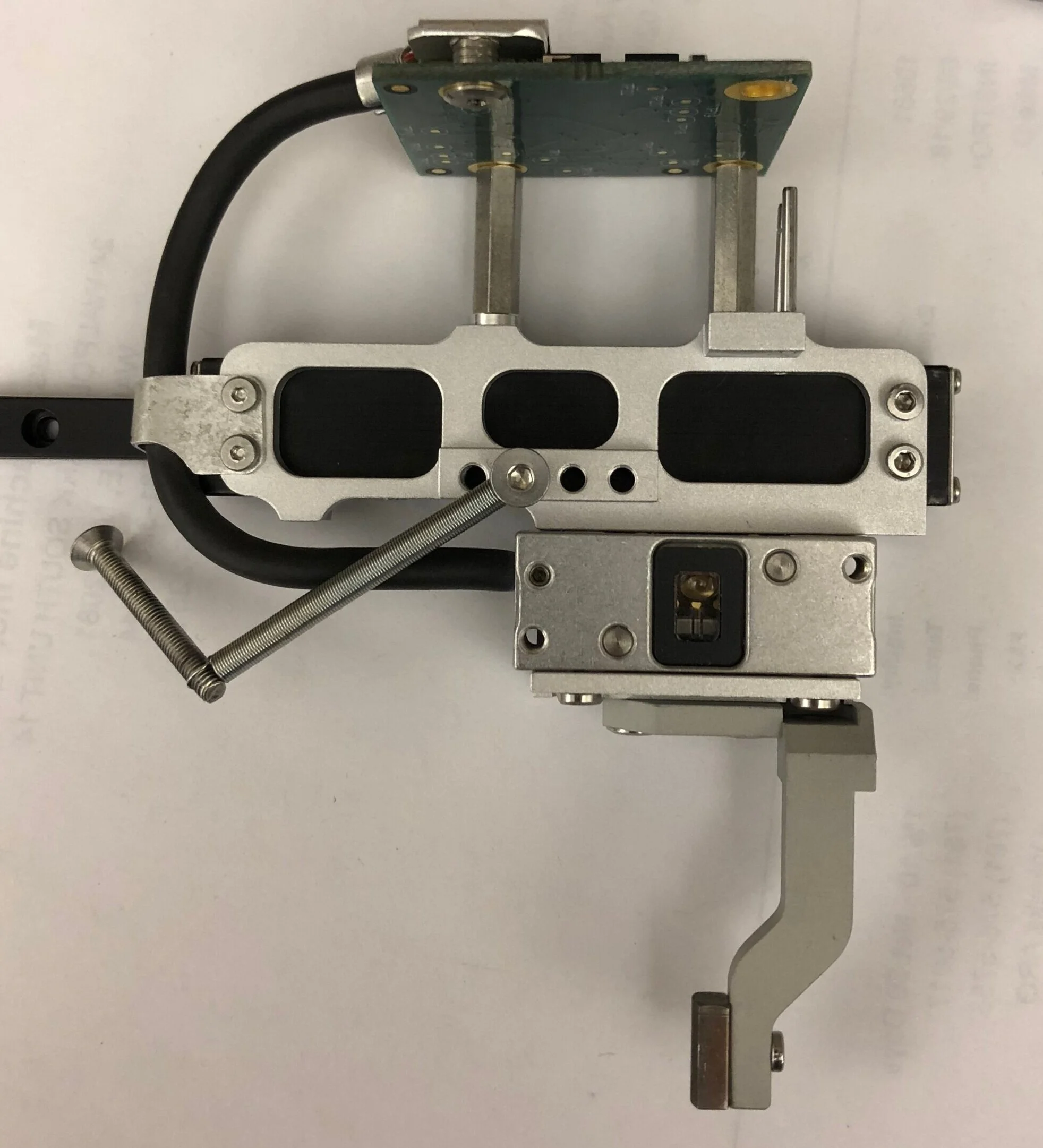

Pictured above is the previous iteration for the bottom portion of the extensometer that contained the scale.

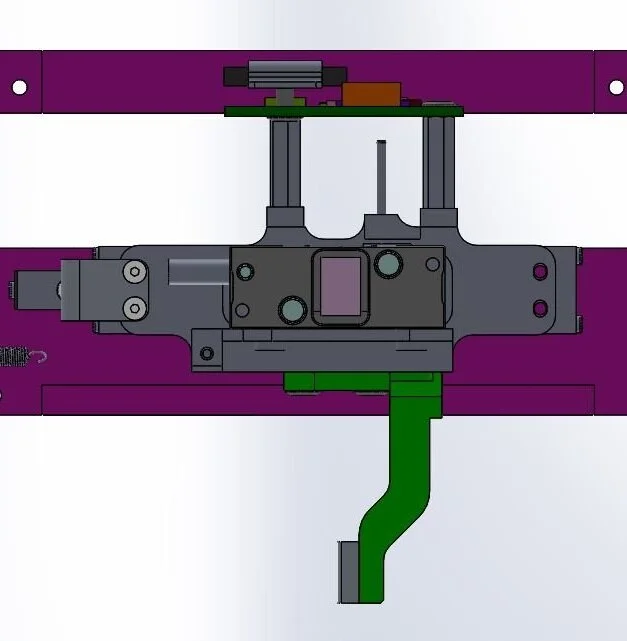

Pictured above is the previous iteration of the top portion of the extensometer that contained the encoder that would read the tick marks of the scale.

Then new design for the bottom portion also moved the scale over the slider to reduce compliance.

The new design reduced the compliance of the part by drastically shortening it and placing the encoder directly over the rollers.

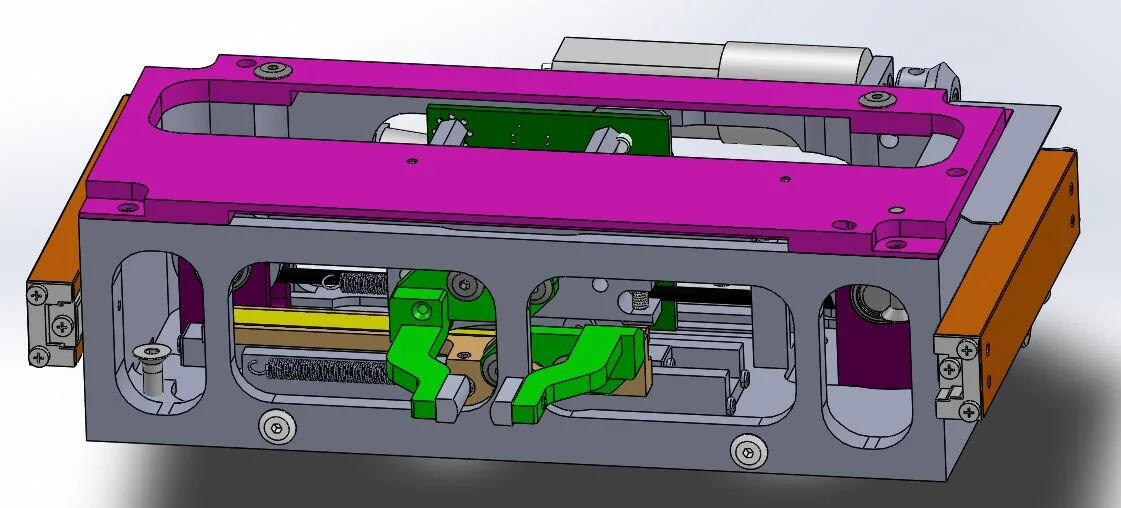

Pictured Above is the new design for the transverse extensometer.